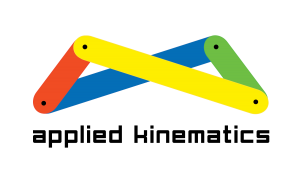

Stretchable Multilayer Structure

► STRETCHABLE MULTILAYER STRUCTURE

► STRUCTURE MULTICOUCHES EXTENSIBLE

SMS – STRETCHABLE MULTILAYER STRUCTURE

European Patent EP2810586A1 – Inventor Patrick Herbault

Purpose of the invention:

In the field of foldable objects, folding must simultaneously deal with:

- folding the structure of the object

- folding the integrated elements of the object, such as, for an armchair, the seat and the back, for a stroller, the fabric and/or the lower tray, for a cart, a platform and/or a partition…

Gradually, as the performance of the folding of the structure progresses in terms of compactness, the point to be addressed becomes the folding of the integrated elements.

Typically, there are many foldable objects for which the integrated folding collapsible element simply is a band of fabric that will be extended when the object is opened. For example a garden or camping chair.

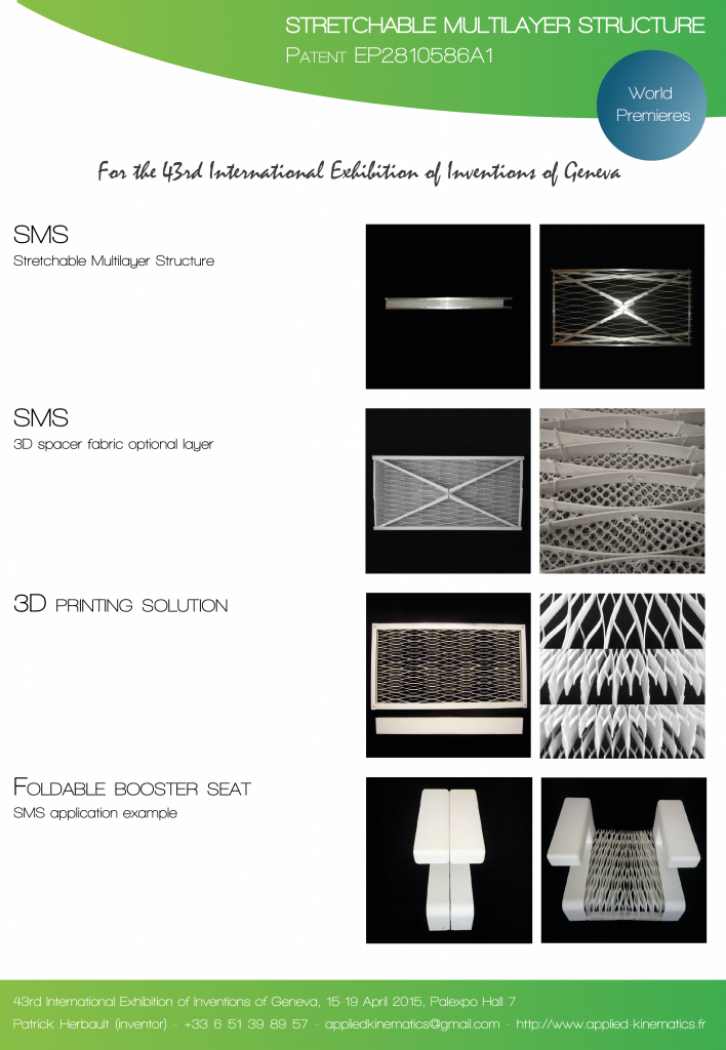

It appears that the most efficient folding patterns are those that fold in 3 dimensions, as for instance, some strollers that add a simultaneous folding along the width do.

The invention offers a more rigid structure, foldable along the width, as an alternative to the stretchable fabric band.

This solution is obtained by combining multiple parallel layers:

- A foldable frame structure

- A set of blades supported by the foldable frame structure

- Optionally, for applications requiring comfort, a layer consisting of a woven three dimensional structure (3D spacer), selected for its ability to be compressed and / or expanded in width.

Different applications of this stretchable multilayer structure are:

- foldable trays to support objects such as the platform of a handling cart, a shopping cart, the lower tray of a stroller, the upper tray of a table…

- with a 3D spacer layer, applications which require human contact, may it be for children or adults such as foldable mattresses, foldable armchairs, foldable wheelchairs…

In both cases, the blades assembly can be achieved by 3D printing and even combine two, three, five sub-layers providing a finer surface mesh while providing good torsional and bending rigidity.