3D FRACTAL CRYSTAL STRUCTURE

Inventor Patrick Herbault

Introducing, an Applied Kinematics innovation, the « 3D fractal crystal structure »!

The invention is related to the 3D printing production process, also called additive manufacturing process.

Nowadays, many baby care products are manufactured, in part, with injected plastic such as polypropylene. The booster seat products can be taken as an example.

The 3D printing process can be used to create prototypes and in some industries like aeronautics to mass produce. In the next decade we believe the 3D printing usage will also increase for baby care products.

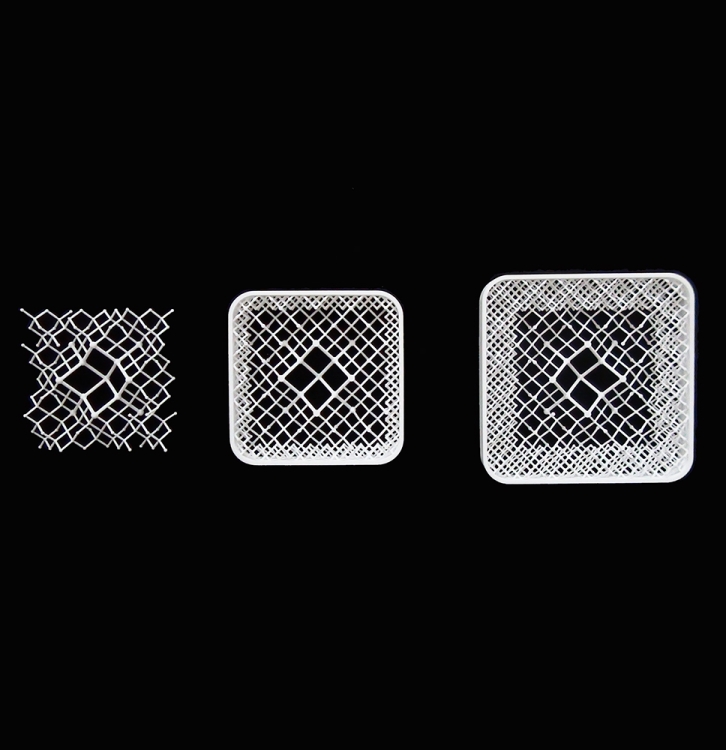

The invention consists in optimizing the manufacturing process of the internal structure of a product of a certain volume, through 3D printing.

Printing a fully filled product in 3D will of course make it very solid but also heavy and more expensive.

The invention is a solution for reducing the volume of the product by offering an optimized internal materials distribution through:

- A lattice type filling structure

- A 3D filling structure based on that of a crystal, in this instance a diamond structure

- A fractal structure where the 3D mesh is thinner near the outside of the product , and the size of which is increased as you move towards the inside

With this solution, we get a one of a kind 3D structure which can be acknowledged one of the most performant in terms of « Very high strength-to-weight ratio for 3D printing ».